A research team at the University of British Columbia has developed a groundbreaking method for producing rayon, a staple fabric in the clothing industry for over a century. This innovative process could reduce chemical usage by as much as 70%, significantly enhancing sustainability in textile manufacturing.

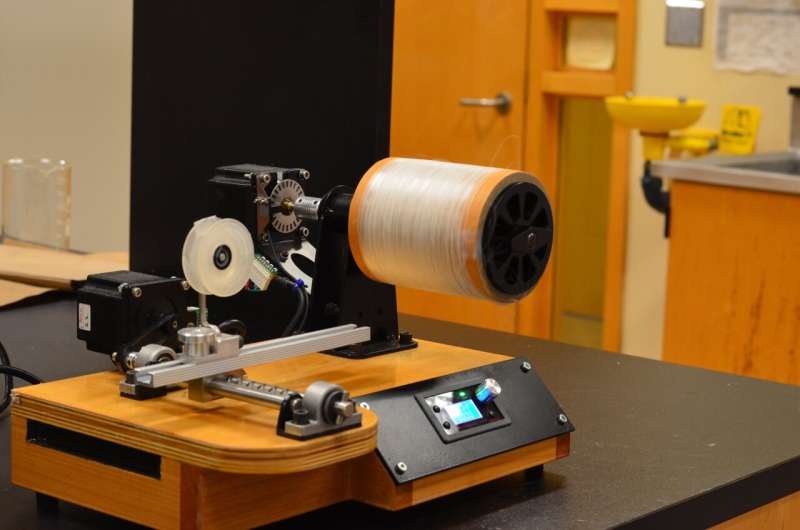

The study, led by UBC Forestry associate professor Dr. Feng Jiang and doctoral student Huayu Liu, introduces a technique for spinning continuous cellulose fibers without the harsh and toxic solvents that are typically utilized in traditional fiber production. The findings were published in the journal Chem Circularity.

Transforming Rayon Production

For more than 130 years, the production of man-made cellulose fibers like rayon has relied on processes that fully dissolve cellulose using large quantities of strong, often hazardous chemicals. UBC researchers approached the challenge differently. They utilized microfibrillated cellulose (MFC)—tiny, hair-like strands of cellulose that can be created through simple mechanical grinding with minimal chemical input.

While MFC is readily available and easier to produce, it often lacks the flow properties necessary for spinning into long, continuous threads. To address this, the researchers incorporated a small amount of softened, dissolved cellulose, which acts as a “glue.” This addition allows the tiny fibers to slide, connect, and twist together, resulting in a strong, continuous thread that can be woven similar to conventional textile fibers.

Liu commented on the breakthrough, stating, “What we found is that we don’t actually need to dissolve cellulose completely to get continuous fibers. By dissolving only a portion of it, we can reduce the amount of solvent needed by as much as 70%—and we can recycle all of it.”

Advancing Sustainability in Textiles

This new method eliminates several steps that typically involve bleaching or harsh chemical treatments, leading to a cleaner, simpler, and more sustainable production process. Dr. Jiang emphasized the importance of these findings, saying, “Making man-made cellulose fiber with less chemical input and far lower environmental impact is a meaningful step. Sustainability isn’t only about the final material—it’s about sourcing the raw material responsibly and ensuring the entire process avoids toxic solvents and minimizes pollution.”

Currently, the fibers have been produced at a laboratory scale, and the research team is exploring opportunities to scale up the production process. They have partnered with Professor Stephanie Phillips at Kwantlen Polytechnic University’s fashion design school to test knitting and weaving prototypes as larger quantities become available.

“We hope these fibers will eventually be used for sustainable clothing and fabric manufacturing,” Dr. Jiang added. “This research shows that a more circular, lower-carbon pathway for textiles is possible.”

The potential for this cleaner production method reflects a significant advancement in textile manufacturing, aligning with global efforts to improve environmental sustainability. As the research progresses, the UBC team remains committed to finding innovative solutions that reduce the ecological footprint of the fashion industry.