NASA and Boeing are collaborating on a groundbreaking initiative to develop flexible wing designs that promise to enhance aircraft efficiency and improve passenger comfort by addressing turbulence. This innovative project aims to create longer, thinner wings that can adapt during flight, thereby reducing drag and mitigating the vibrations associated with turbulent conditions.

Advancements in Wing Design

The partnership, known as the Integrated Adaptive Wing Technology Maturation, focuses on testing a wing model with a higher-than-usual aspect ratio. This research seeks to maximize efficiency while addressing the challenges posed by flexibility in flight. Such wings are expected to handle greater aerodynamic forces, including wind gusts and maneuver loads, more effectively.

According to Jennifer Pinkerton, an aerospace engineer at NASA Langley Research Center in Hampton, Virginia, “When you have a very flexible wing, you’re getting into greater motions. Things like gust loads and maneuver loads can cause even more of an excitation than with a smaller aspect ratio wing.” The goal is to harness the advantages of higher aspect ratio wings, which are typically more fuel-efficient, while maintaining control over the aircraft’s aeroelastic response.

Addressing Wing Flutter

One significant concern with long, thin wings is the risk of flutter, a phenomenon where the aircraft vibrates uncontrollably due to aerodynamic forces. This can lead to turbulence and compromise safety. Current research aims to characterize aeroelastic instabilities in wing concepts to prevent such occurrences.

NASA and Boeing are focused on how to reduce wing loads during maneuvers and turns, thereby lessening the likelihood of flutter. Effective management of these challenges is anticipated to enhance overall aircraft performance, reduce fuel consumption, and create a more pleasant experience for passengers.

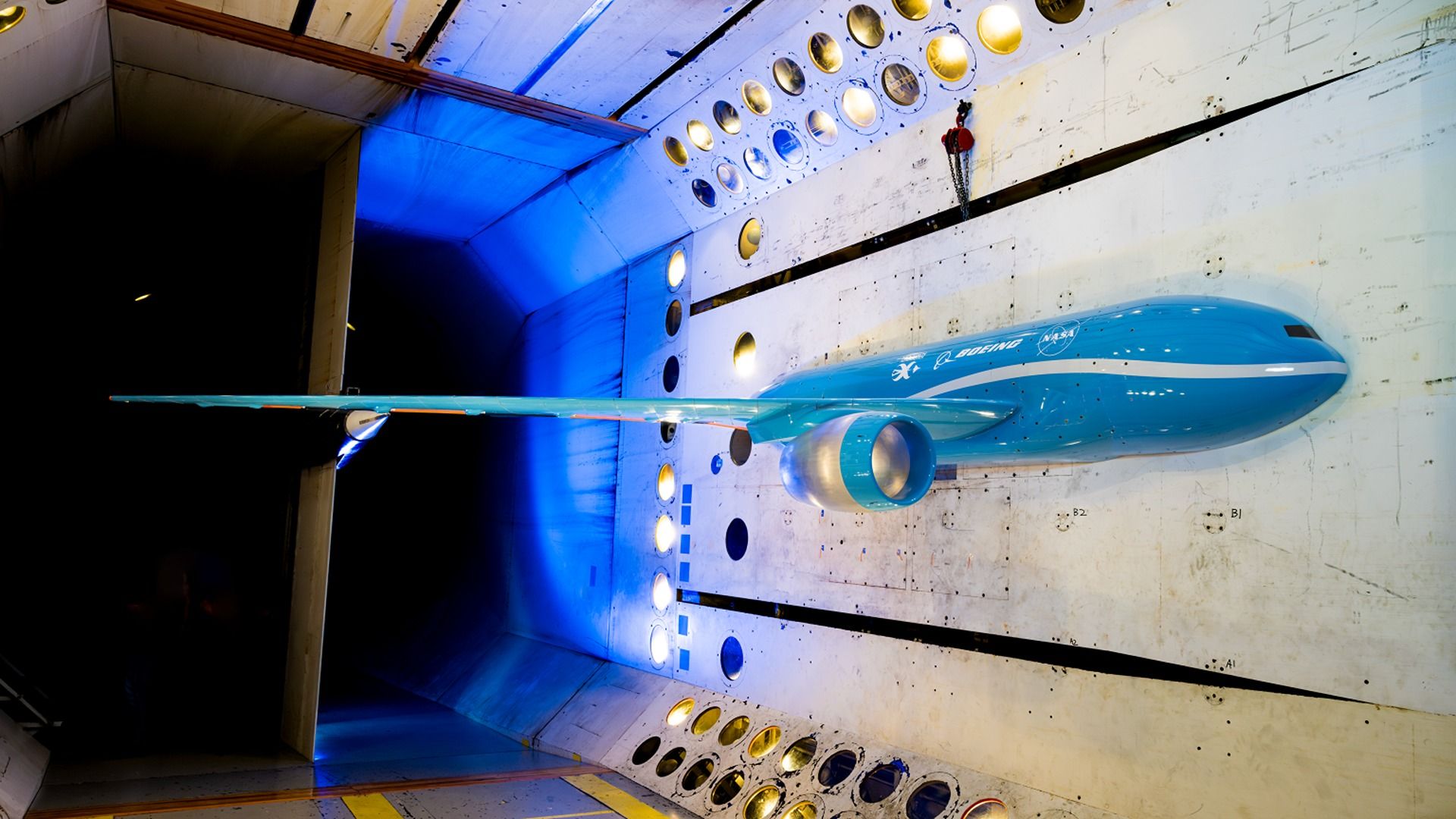

Testing for flutter is being conducted in controlled environments, as full-scale aircraft testing is impractical. The Nasa Langley Transonic Dynamics Tunnel, measuring 16 feet high by 16 feet wide, provides an ideal setting for these experiments, allowing for large-scale model testing.

The research also involves a scaled-down aircraft model developed in partnership with NextGen Aeronautics. This model, resembling the right-hand side of a standard-sized airplane with a wingspan of 13 feet, has been mounted in the wind tunnel. Researchers can manipulate airflow and control surfaces to assess the wings’ durability under various conditions.

Instruments and sensors installed within the tunnel measure the forces acting on the model, providing critical data to refine wing designs. The initial tests, conducted in 2024, established baseline readings for comparison against future models. Recent findings indicate significant reductions in wing shaking, a promising development for the next generation of aircraft.

The collaboration falls under the NASA Advanced Air Transport Technology project and is part of the agency’s Advanced Air Vehicles program, which operates under the NASA Aeronautics Research Mission Directorate. The ongoing research aims to develop new technologies that could revolutionize the future of aviation, making flights safer and more efficient for travelers around the world.